Restaurants

Refrigeration & Freezers , Gas Stoves & Induction , Food Processors

Efficient mobility, hygiene, and work safety.

Efficient mobility, hygiene, and work safety are key.

Clearly delineate cooking, storage, and cleaning areas to allow chefs and staff to move around smoothly.

It's also important to keep food storage and cooking areas separate, and to have fixtures that are easy to clean, to ensure hygiene standards are met.

Finally, consider the distance between fire and electrical installations and design the structure to prevent fire and safety accidents.

Efficient Workflow, Hygiene Management, and Work Safety

It is essential to clearly separate cooking, storage, and cleaning areas to ensure a smooth workflow for chefs and staff. Additionally, to comply with hygiene standards, food storage and cooking areas should be kept separate, and easily cleanable equipment should be installed. Lastly, the layout should be designed with proper spacing between fire and electrical equipment to prevent fire hazards and safety accidents.

Coffee

Espresso machines & coffee grinders, blenders and ice makers

Optimize barista movement, speed customer service, and manage hygiene

Optimizing barista movement, speed of customer service, and hygiene are key.

Frequently used equipment, such as espresso machines, grinders, refrigerators, and ice machines, should be centralized and designed for quick action.

It's also important to separate pickup zones and workspaces to ensure a seamless process from ordering to serving drinks, and to have circulation routes that minimize travel between employees.

Finally, make sure you have enough space to wash cups and utensils to ensure good hygiene and allow for quick turnover.

Optimization of Barista Workflow, Customer Service Speed, and Hygiene Management

Frequently used equipment such as espresso machines, grinders, refrigerators, and ice makers should be strategically placed in one area to enable quick and efficient operation. Additionally, to ensure a smooth process from order to beverage delivery, the pickup zone should be separated from the workspace, and the layout should minimize staff movement. Lastly, ample space for washing cups and utensils must be secured to maintain strict hygiene standards and facilitate quick turnover.

Hotel/Buffet

Large Refrigerators-Freezers , Large Gas Stoves & Ovens, High-Speed Food Processing Machines

Efficiency in bulk cooking, optimize worker flow, and manage hygiene and safety

Efficiency in bulk cooking, optimizing work flow, and managing hygiene and safety are paramount.

Cooking, cleaning, and storage areas should be clearly separated to allow chefs and staff to work simultaneously and with smooth circulation.

It's also important to centralize key equipment, such as stoves, ovens, and refrigerators, and increase access to ingredients and cooking tools so that you can quickly prepare a variety of dishes.

Finally, you'll need to design a robust ventilation and exhaust system to quickly expel the smoke, heat, and moisture generated by mass cooking.

Optimal Kitchen Layout for Hotel Cooking Facilities

In hotel kitchen facility layout, efficiency in mass cooking, optimized workflow, and hygiene and safety management are of utmost importance. The cooking, washing, and storage areas should be clearly separated to ensure that chefs and staff can work smoothly at the same time. Additionally, to facilitate the rapid preparation of various dishes, essential equipment such as gas stoves, ovens, and refrigerators should be centrally positioned, enhancing accessibility to ingredients and cooking tools. Lastly, a powerful ventilation and exhaust system must be designed to quickly remove smoke, heat, and humidity generated during large-scale cooking.

Deliveries/Dispensations

Professional fryers, griddles, and grills: everything you need for the fast food sector

Maximize cooking speed, space efficiency, and sanitation

To ensure that delivery orders are processed quickly, cooking areas, packaging areas, and delivery routes should be clearly delineated, and equipment should be laid out so that operations require minimal movement.

In addition, to maintain high productivity in a small space, it is effective to utilize multi-functional equipment (combi ovens, multifunctional cookware) and to combine work surfaces and refrigerators into a single unit.

Finally, with large quantities of food being cooked in a short amount of time, it's important to keep the movement of raw ingredients and cooked food separate to maintain hygiene and food safety.

Optimized Kitchen Layout for Delivery-Only Restaurants

To ensure quick processing of delivery orders, the cooking area, packaging zone, and delivery flow should be clearly separated, with equipment arranged to minimize movement. Additionally, to maintain high productivity in a compact space, multifunctional equipment such as combi ovens and versatile cooking appliances should be utilized, and integrating workstations with refrigerators can be an effective solution. Lastly, since large-scale cooking happens in a short time, strict separation of raw ingredients and prepared food workflows is crucial to maintaining hygiene and food safety.

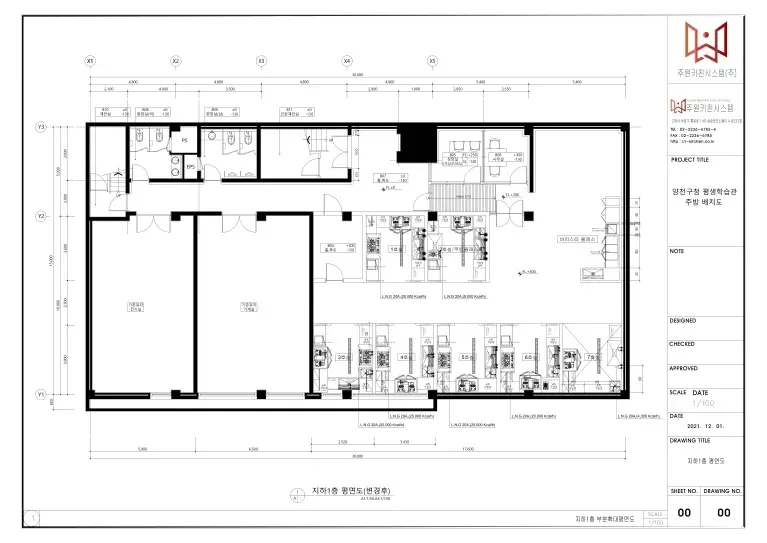

Public organizations

Kitchen equipment to HACCP standards

Optimize mass feeding efficiency, hygiene and safety, and worker mobility

With hundreds to thousands of meals served per day, cooking, serving, and cleaning areas should be clearly separated, and large-scale equipment suitable for high-volume cooking (large gas stoves, braising pans, conveyor dishwashers, etc.) should be deployed.

It is also essential that food storage and cooking areas are well separated for hygiene purposes, and that pathway design is aligned with HACCP standards.

Finally, you should consider the safety and comfort of your workers and install adequate ventilation systems, non-slip flooring, and ergonomic workstations.

Optimized Kitchen Layout for Public Institution Cafeterias

In the kitchen layout of a cafeteria within a public institution, efficiency in mass meal preparation, hygiene and safety, and workflow optimization for staff are top priorities. Since hundreds to thousands of meals are served daily, the cooking, serving, and dishwashing areas must be clearly separated, and large-scale equipment such as industrial gas stoves, braising pans, and conveyor dishwashers should be installed to accommodate bulk cooking.

Additionally, for proper hygiene management, food storage and cooking areas must be strictly separated, and workflow design should comply with HACCP standards. Lastly, to ensure worker safety and convenience, the kitchen should be equipped with a sufficient ventilation system, non-slip flooring, and ergonomic workstations.

Privacy policy

Statistics & Analytics

Collecting personal information in analytics

Data Collection: Cookie, Data

Retention period of personal information

Records for support inquiries: 30 days

Contact us

Required: Email, cell phone

Optional: Name, fax number

Privacy Officer

Customer Support

Customer Support

140, Tongil-ro, Deokyang-gu, Goyang-si, Gyeonggi-do

Samsong Techno Valley Building A, Room B131